News Center

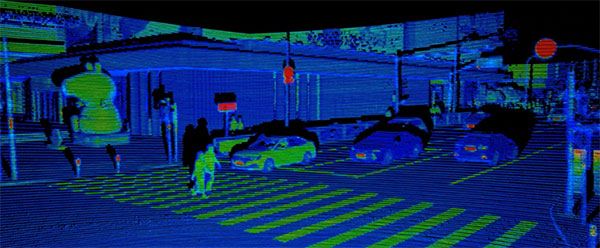

Hangzhou Gaopin Automation Equipment Co., Ltd. recently completed the image-level ultra-long-range Lidar assembly line for the global Tier1 supplier. This production line integrates the latest intelligent assembly line technology of high-efficiency collaborative new energy vehicle key components of Gaopin Automation Co., LTD., filling the gap in the field of intelligent and efficient collaborative assembly technology of domestic image-level ultra-long-range lidar. It has enabled customers to realize major changes in collaborative digitization, process digitization, manufacturing digitization and operation and management digitization of intelligent manufacturing. The LiDAR products produced by this production line will be used in batches for the first echelon of new energy vehicle Ovens in China.

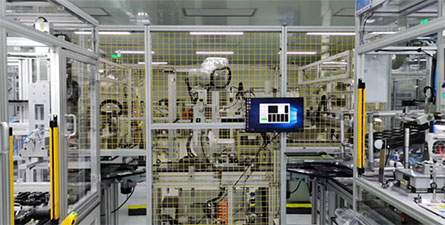

Image level ultra long range Lidar intelligent assembly line

The product of the production line solves the key technologies such as digital twin-driven assembly line optimization technology, multi-intelligent robot collaborative manufacturing technology, man-machine collaborative assembly decision-making based on edge computing, production resource self-reconstruction and scheduling optimization technology, and assembly line big data analysis results feedback technology. It solves the current situation of high manual degree of LiDAR assembly, improves various assembly accuracy, improves product assembly quality, and realizes the digital upgrade of production line. The whole line beat reached within 80s, equipped with quick change technology, compatible with multiple product specifications, and the production line flexibility and intelligence reached the industry-leading level.

In recent years, electric vehicles have become the development trend of the automotive industry, and the related industry chain has attracted much attention, among which the lidar heat, which is regarded as the "eye" of intelligent driving vehicles, continues to rise, and the market demand is huge. The full-industrial high-performance LiDAR production line jointly built by Gaopin Automation and customers has achieved a high degree of automation and digitalization, with robot sealant coating, automatic tightening assembly, automatic calibration test, automatic parameter calibration and other functions. Production line data input and analysis in real time to ensure the authenticity, integrity and traceability of data; Through highly automated and digital production line construction, it helps customers achieve mass production while bringing higher product consistency and reliability, improving production efficiency and reducing production costs.

Long range laser radar long range detection to ensure driving safety

【 Company Profile 】

Hangzhou Gaopin Automation Equipment Co., LTD., founded in 2013, headquartered in Hangzhou, after more than 10 years of research and development results, has become an outstanding supplier in the field of intelligent manufacturing, and has national high-tech enterprise certification, provincial enterprise research institute and other qualifications and 167 patents + software works.

As a national high-tech enterprise for Industrial 4.0 intelligent manufacturing solutions, Gaopin has always adhered to the development concept of high quality and permanent innovation, and focused on providing customers with stable, reliable and innovative automation system solutions.

With three wholly-owned subsidiaries in the world, four domestic offices and four overseas offices, Gaopin serves many of the world's top 100 auto parts enterprises with high efficiency and high quality. With the process of globalization and the accumulation of research and development technology experience, Gaopin will be based in China, serve the world, actively layout the European and Asia-Pacific markets, and build a global business service network.

Return to Overview