News Center

During the steering process, the steering gear may make uncomfortable noises, especially on electric vehicles. Schaeffler has introduced a new pendulum bearing to solve this problem.

-Smooth and low noise: Schaeffler's new pendulum bearings are suitable for electric vehicle applications

-As a positioning bearing, it effectively reduces the friction torque in the turbo worm mechanism

-Schaeffler ball screw drives for heavy vehicle and SUV applications

Herzogenorach, Germany, Feb. 28, 2019 / PRNewswire /-- Electromechanical integrated steering systems have become an indispensable technology in modern cars, as such systems not only reduce fuel consumption, but also help improve driving comfort. Car drivers want smooth steering, especially when steering or parking. Many consumers are already using fully automated parking assistance systems. However, during the steering process, the steering gear may make uncomfortable noises, especially on electric vehicles. Schaeffler has introduced a new pendulum bearing to solve this problem.

There are four electric power steering systems available worldwide

Today, automotive electric power steering systems worldwide can be divided into four types. In rack electric power steering systems, the motor shaft is parallel to the rack shaft, which is commonly used in heavy vehicles, SUVs and small trucks to provide maximum steering torque. In this steering system, the motor drives the ball screw unit through a belt. The main shaft of the ball screw drive unit is directly connected with the rack. Schaeffler develops and produces a range of ball screw drives for use in such steering systems.

In small and light vehicles, electric power steering is achieved by steering column assistance, known as tubular electric Power steering (EPSC). On medium and heavy duty vehicles, electric power steering is implemented through a power assist system on the rack, which directly acts on the pinion of the mechanical steering mechanism, known as pinion electric power steering (EPSsp). In this application, an electric gear device can also be added to the rack, and the steering torque can be transmitted to the rack through two pinion gears, such a steering system is called double pinion electric Power steering (EPSdp). In general, the power provided by the motor transfers the steering torque either directly to the steering shaft EPSc on the steering column or directly to the steering rack (EPSsp and SPDp) through the turboworm mechanism.

New pendulum bearings help reduce friction and noise

For a steering system using a turbine turbine mechanism, the steering bearings must meet several special requirements at the same time. First of all, because it plays the role of positioning the shaft and is responsible for supporting the cochlea, it must be able to withstand the load from both axial and radial directions; Secondly, it has to be able to counteract the noise generated in the system. This is because the worm transmits the motor torque to the turbine through the spiral teeth, causing the worm to move in the vertical direction, making the bearing tilt. The use of traditional ball bearings in this case often leads to an increase in noise and friction torque, which affects the performance of the gear unit.

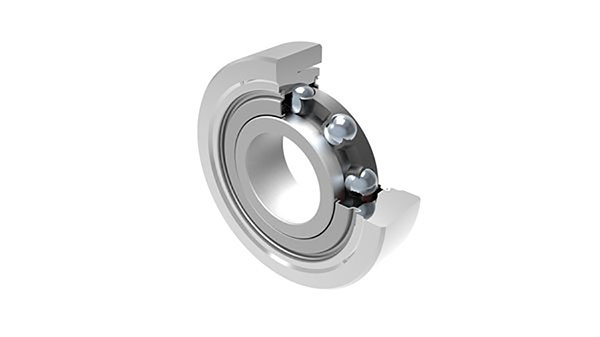

In response to this situation, Schaeffler has developed an innovative pendulum bearing with an aligning outer ring of special curvature. Thanks to the new design, the bearing inner ring can automatically tilt, thereby compensating the rotation Angle of the cochlear, avoiding the increase of friction torque and noise. An added benefit of this design is that the worm can be pre-tightened radially, so that there is no gap between the worm and the turbine. In this way, the "clicking" sound often appears in steering can be reduced - when the direction of the vehicle changes, the direction of rotation of the worm changes with it, the noise emitted when the reverse tooth surface engages. The rotating motion of the new pendulum bearing also compensates for mounting errors in the bearing housing.

The pursuit of detail: Solutions for electric vehicles

Today's consumers have been accustomed to enjoying a quiet and comfortable environment in the car, and the noise generated by the use of power steering during vehicle control and parking can cause extreme discomfort to consumers. This is especially true during automatic parking, when the vehicle turns continuously and rapidly, or when the vehicle itself is an electric vehicle, because the electric vehicle has no engine noise and cannot mask other noises or vibrations. With this bearing, Schaeffler once again demonstrates its commitment to promoting the popularization of electric vehicles - not only in the complex electric drive system, but also in the subtleties of product design.

Steering gears can make uncomfortable noises when the vehicle turns, especially on electric vehicles. Schaeffler has introduced an innovative pendulum bearing to solve this problem. The bearing adopts a special arc aligning outer ring, which can make the inner ring of the bearing tilt automatically, so as to compensate the rotation Angle of the cochlear, and avoid the increase of friction torque and noise.

Source: (Schaeffler Group)

Return to Overview