News Center

A "T" is a good thing. Do you have a car?

Looking at the entire automotive market, Turbo Boost is increasingly becoming a mainstream trend. Every type of car, all with a "T". It seems that having a "T" at the end of the car makes it look taller, and it does.

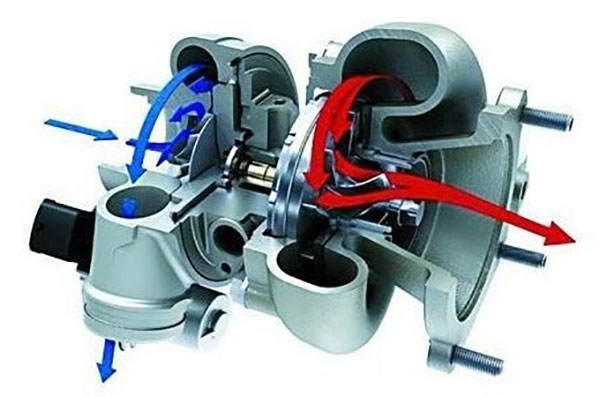

Compared to naturally aspirated engines, turbocharged engines have a more powerful engine power output in terms of power performance. At the same time, the displacement can be reduced and the fuel combustion ratio can be increased to a certain extent.

The rated speed of the general 4-cylinder turbocharger is about 130,000-150,000 RPM, the ordinary turbine engine can reach 600 ° C soon after starting, the turbine using AGV technology will produce a high temperature of 1000 ° C, and the maximum temperature of the Bugatti Veyron four-turbine engine can break through 1600 ° C.

At present, the strong market demand of turbochargers and the high speed and high operating temperature of turbochargers themselves have put forward the requirements of production rhythm improvement, high precision assembly and high stability for equipment manufacturers.

Turbocharger as a core component, its importance to improve the efficiency of the engine is self-evident. Key components such as oil pumps, OCV valves and EGR coolers related to superchargers are also indispensable.

Oil pump

When the engine is running, in addition to lubricating other parts, the oil pump also lubricates the rotating shaft of the turbocharger through the oil passage, and transmits low-temperature lubricating oil to the turbine bearing to take away the heat of the turbine.

OCV valve

The OCV valve changes the oil flow and flow in the oil circuit, adjusts the timing Angle of the camshaft, so as to adjust the amount of intake (exhaust) and the opening and closing time of the valve.

EGR (Waste Recycling System)

EGR and turbocharger are the two flow directions of the exhaust gas part of the engine. Once the EGR is turned off, the pressure before the vortex increases, and if the turbine speed exceeds the safe upper limit, the service life of the supercharger will be shortened.

The parts assembly line of the above oil pump, OCV valve and EGR system is the same as the supercharger production line, which has high requirements for production rhythm and assembly accuracy.

Looking at the current auto parts market, it is basically monopolized by foreign capital. Component assembly testing technology is the core technical threshold. In Hangzhou, there is such a high-end equipment localization of auto parts intelligent manufacturing system integrator - Hangzhou Gaopin Automation Equipment Co., LTD., in the field of auto parts assembly test has formed a full set of assembly test solutions, its turbocharger assembly line has occupied 80% of the national market share.

Hangzhou Gaopin automated assembly and test line, in the domestic peers stand out, can not be separated from the following advantages. Take the turbocharger assembly line as an example:

(1) Stable

Gaopin MES2.0 system manages and monitors the assembly process.

136 assembly error prevention, eliminate the process problems that may occur in the assembly process. The EOL test equipment developed by Gaopin can detect quality defects that cannot be 100% detected during the production process.

(2) Fast

Industry-leading assembly time, a turbocharger can be assembled in just 60 seconds. The supercharger core has been fully automated assembly.

(3) Accurate

The detection accuracy of blade clearance and vortex clearance is accurate to: 0.01mm (equivalent to the diameter of pm10 haze particles).

Product assembly pass rate >99.99%

A "T" is not enough for a good car. Water pump/oil pump/vacuum pump, VVT phaser, EPS power steering, i-Booster booster, sensor and other tens of thousands of parts together to form a complete car. The accuracy, quality reliability and stability of these parts are guaranteed by auto parts assembly test equipment manufacturers such as High quality Automation.

With T cars on the road more and more, with T cars are more and more fuel efficient, the hero behind the scenes is constantly working hard for the core technology of parts assembly line localization.